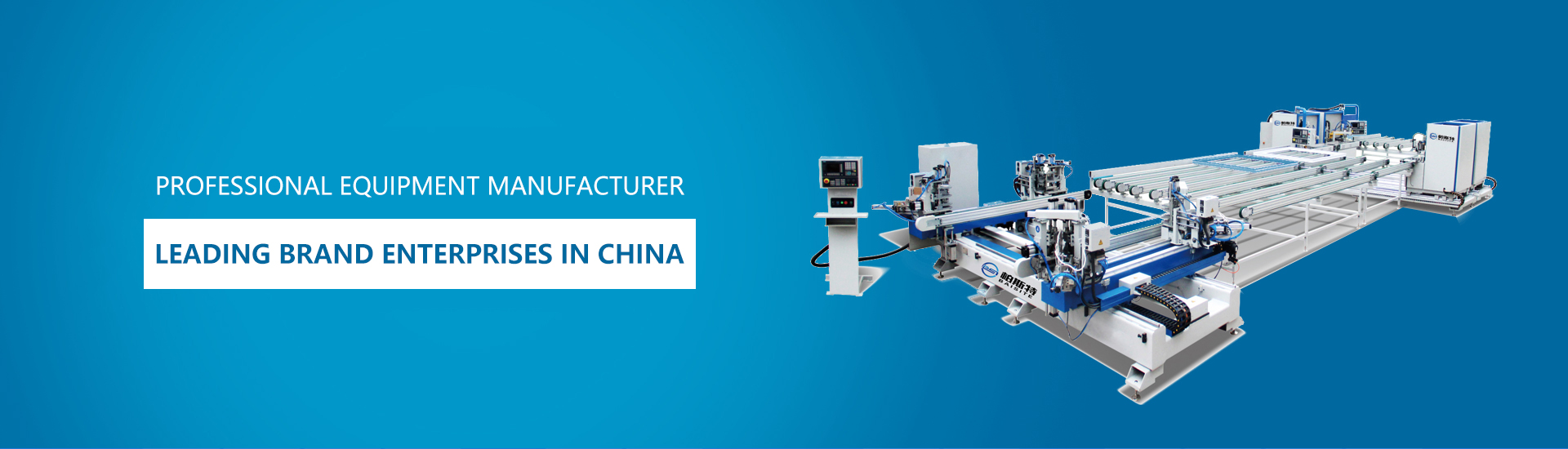

Aluminum plastic profile sawing and milling machining center SJMCX02

Processing content:

This machine is a specialized equipment for drilling, milling, and sawing aluminum and plastic profiles. It can complete profile drilling, milling, and cutting at any angle (30 °~150 °) in the horizontal plane of the profile on the basis of one feeding.

Equipment features:

The automatic feeding worktable can continuously and automatically clamp profiles for cutting and processing.

The device has a dual saw blade structure, with an arbitrary angle saw blade on top and a 45 ° specialized cutting saw blade on the bottom, resulting in high efficiency.

The moving parts are all equipped with high-precision linear guide pairs, which run smoothly and ensure machining accuracy.

The three-axis CNC of the robotic arm is adjustable and memorable, automatically rotates, and can achieve flow operation with automatic material recovery. Equipped with monitoring, it is safer to observe through the screen.

☆ The robotic arm adopts imported high-precision gears and racks to ensure feeding accuracy.

The drilling and milling section is equipped with multiple spindle motors, which can drill holes and mill grooves on all four sides of the profile.

☆ Imported motor directly connected saw blade, smooth cutting, high processing accuracy; Ensure stable and reliable operation of the equipment.

Equipped with barcode printing function; Automatic material recycling function.

☆ The shell is fully enclosed to ensure the safety of operators.

☆ Connect door and window software, ERP software, and automatically transmit data to achieve digital factory (optional).

Aluminum profile processing can add laser drilling and marking functions (optional).

Main technical parameters:

Power supply: 380V 50Hz Total power: 30kW

Working pressure: 0.6-0.8MPa Sawing motor power: 3.0kW

Drilling and milling spindle motor power: 6 × 3.0kW motor speed: 2800r/min

Laser power: 3.0KW

Cutting length: 350-6000mm

Repetitive positioning error: ± 0.05mm

Saw blade specification: Φ 550 × Φ 30 × 4.4mm × 120TP

Milling and cutting profile height: 30-120mm

Milling and cutting profile width: 30-120mm

Dimensions: 16860 × 3350 × 2000mm

Hotline:

Hotline: