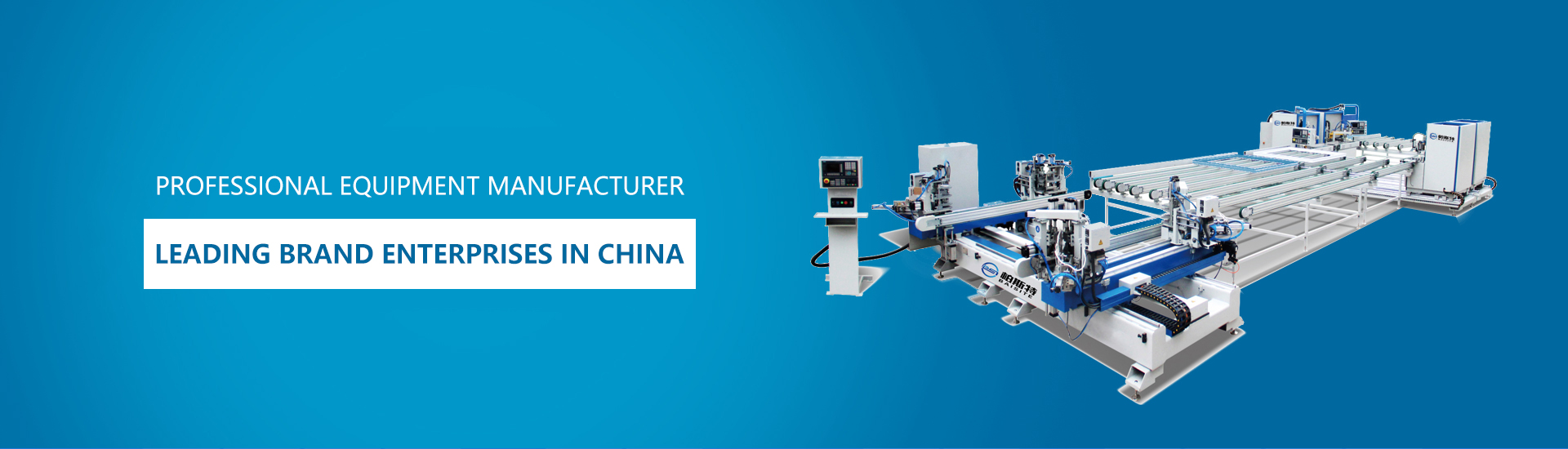

Aluminum door and window CNC four head corner assembly machine LZJ4-CNC-3000

Features:

This machine is used for efficient assembly of aluminum doors and windows, and can complete the corner code stamping connection of four corners at once.

The clamping device automatically moves forward and backward, easy to operate, and the window size is automatically adjusted.

The rack is made of professional welding materials from Ansteel and has undergone aging treatment.

☆ Adopting high-quality Mitsubishi CNC system from Japan, balancing speed and accuracy.

Through the torque monitoring function of the servo system, automatic pre tightening of the four corners is achieved, ensuring the accuracy of the angle assembly.

The angle cutter is easy to adjust in front, back, left, right, and adapt to the needs of different profiles.

One time framing can control the joints and flatness between profiles, making the quality of framing predictable.

The seamless connection between the control system and servo system greatly improves control accuracy.

Main technical parameters:

Power supply 380V 50Hz

Rated power 7.5kW

Rated pressure 15MPa

Gas source working pressure 0.5-0.8MPa

Fuel tank capacity 60L

Suitable for profile width of 93mm

The maximum frame size is 2200 × 3000mm and the minimum is 480 × 480mm

Dimensions 4700 × 2200 × 2600mm Weight 2200kg

Hotline:

Hotline: