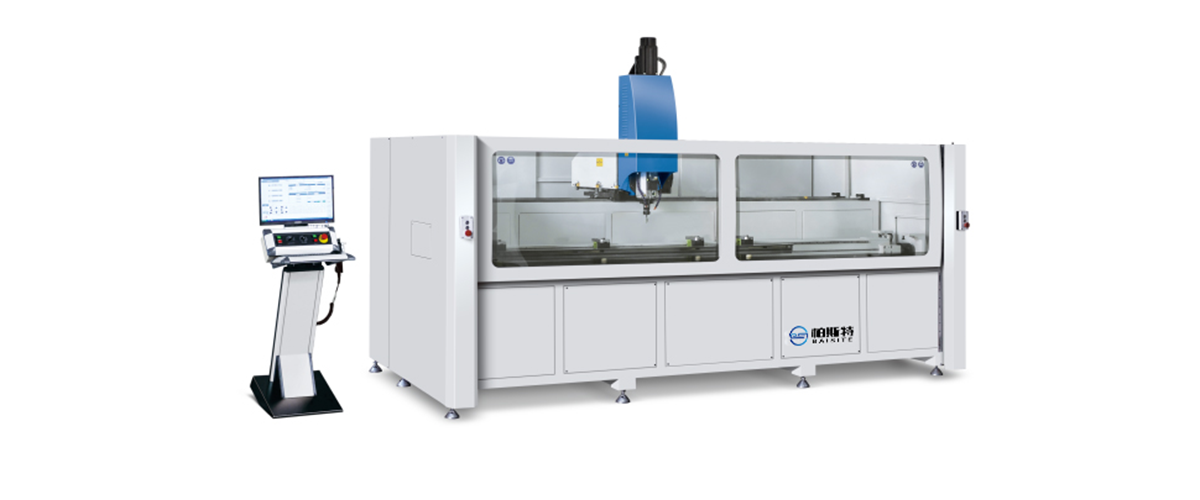

Aluminum profile CNC drilling and milling machining center LGZ4-CNC-3000

Characteristic:

☆ Suitable for CNC drilling and milling of various parts such as aluminum alloys, copper, PVC profiles, and sheets.

☆ Adopting high-precision linear guide pairs, ball screws, gear racks, and imported servo systems to ensure smooth motion and high positioning and processing accuracy.

☆ Adopting imported high-speed automatic tool changing electric spindle, with stable and reliable performance.

Both ends of the workbench are equipped with positioning devices, which can achieve dual working area processing of short materials, greatly improving work efficiency.

Adopting a semi enclosed cover and bottom feeding tray, it has high safety and effectively avoids the pollution of aluminum shavings to the working environment, creating a good working environment.

The workbench can be automatically flipped to achieve continuous processing of the three sides of the profile.

The intelligent CNC system and simple and intuitive human-machine interface make operation more convenient and efficient.

The rotatable worktable can be freely converted between three positions: -90 °, 0 °, and+90 °, achieving milling of three surfaces with one clamping.

☆ Three axis CNC movement of the machine head, high precision, and CNC axis control can be selected for the three sided flipping of the worktable;

☆ Manual movement and positioning of workbench fixtures; You can also choose CNC axis control (optional);

☆ Machines can be customized according to the length of the material.

Main parameter description

X/Y/Z axis stroke 3000mm 450mm 350mm

X/Y/Z axis movement speed 0-60m/min 0-30m/min 0-30m/min

Spindle power/speed 7.5kW/9kW 24000r/min

Spindle taper hole ISO30

Knife magazine layout

Knife storage capacity T 3pcs

Power supply 380V 50Hz

Air pressure 0.5~0.8MPa

Dimensions 4500 × 2300 × 2050mm

Weight 2500kg

Hotline:

Hotline: