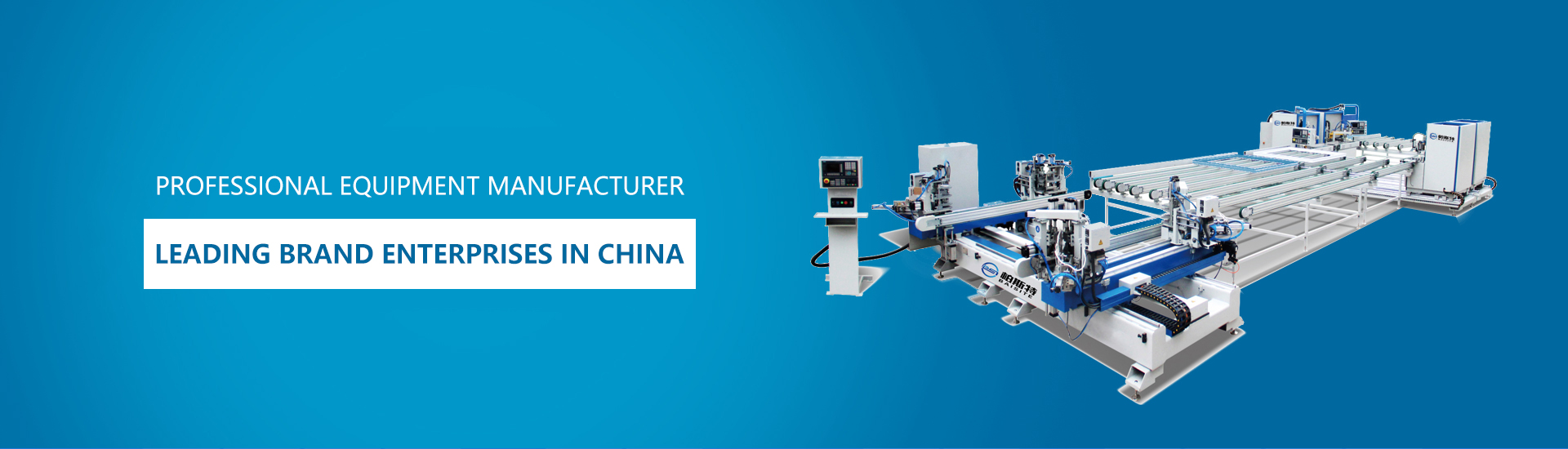

Aluminum profile three-axis CNC end milling machine LJDX-CNC-3+2

Function:

Used for high-precision machining of tenon joints and step surfaces of different profiles such as mullions

characteristic:

Milling multiple profiles at once with high efficiency.

One spindle motor paired with two saw blades.

CNC structure, no need to manually adjust cutting tools, high-precision machining of tenon step surfaces can be completed in one go;

The up and down, as well as the forward and backward movement of the cutting tool, are controlled by servo CNC axes, making it easy to adjust and highly accurate. It is particularly suitable for efficient production and processing of system doors and windows;

Selecting high-power and high-precision spindle motors with good milling effect and high stability;

One loading can meet the high-precision processing of multiple materials;

Enhance the compression positioning structure to ensure milling accuracy;

Floating limit device with high positioning accuracy

The bed is designed with ultra-high rigidity, and the feed system adopts servo motor movement, with adjustable speed and position. The cutting feed is smooth, the machining accuracy is high, and the surface quality is good.

More user-friendly chip removal design, easier maintenance and upkeep

The CNC system can memorize multiple sets of programs and directly process them based on the profile input program.

Main technical parameters:

Power supply: 380 V 50 Hz, three-phase five wire

Power: 3.0 kW

Working pressure: 0.5~0.8 MPa

Gas consumption: approximately 100 L/min

Saw blade specification: φ 350 × φ 32 × 3.0 × 120T

Saw blade speed: 2800 r/min

Milling depth: 100 mm (maximum)

Milling height: 230 mm (maximum)

Dimensions (L × W × H): 2400 * 1500 * 1600 mm

Weight: Approximately 1100 kg

Hotline:

Hotline: