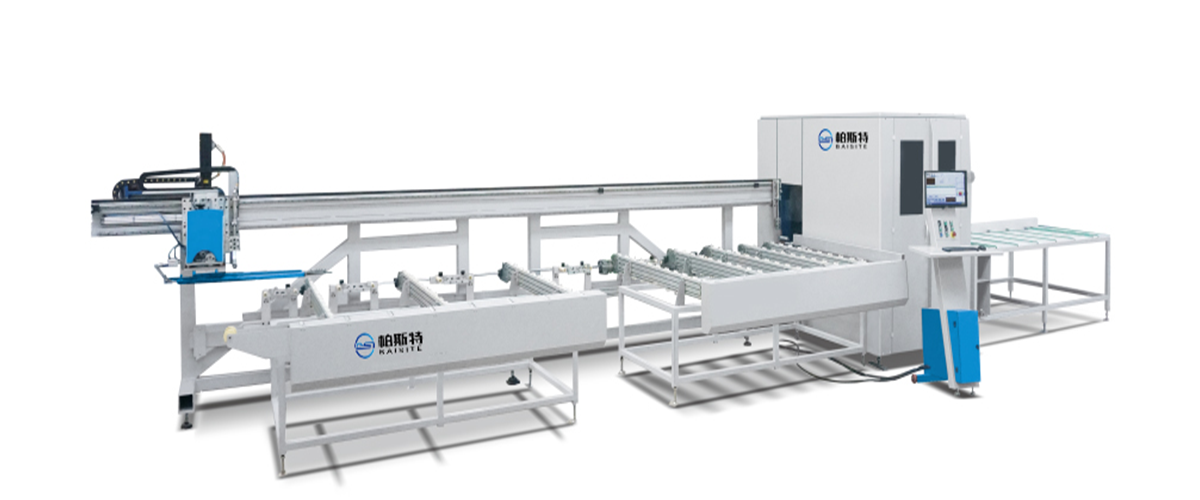

Aluminum plastic profile sawing and processing center LJMC02

Function:

Automatic cutting of PVC and aluminum alloy profiles to -45 °, 90 °, and 45 ° lengths, suitable for large-scale production of high-end doors and windows.

characteristic:

The robotic arm adopts three-axis CNC control, and there is no need to adjust when changing materials, ensuring accurate positioning; Circular feeding, automatic completion of profile clamping, feeding, and cutting, with a high degree of automation; Significantly improved production efficiency.

☆ Servo motor paired with gear rack high-speed feeding system, high precision and production efficiency.

☆ Adopting the latest dual motor module structure, the upper part can cut the saw blade angle arbitrarily, and the lower part has a fixed 45 ° cutting angle; High precision spindle motor with high machining quality.

The entire machine adopts linear motion auxiliary guide rails to ensure long-term rust prevention and high dimensional accuracy of processed products.

Equipped with an automatic discharge system and an automatic material head collection system, the working environment is clean, and the operation is simple and convenient.

☆ All use imported high-quality electrical and pneumatic system components, with high stability and reliability.

The height design of the console and body conforms to ergonomic principles, reducing the labor intensity of workers.

This machine is particularly suitable for batch and high-quality production of complex window types.

Configure a barcode printer to print material identification in real-time, achieve process information identification, and facilitate material management.

☆ It can communicate with the upper computer, automatically select processing tasks, and can be connected to ERP software (optional).

Main technical parameters:

Working pressure 0.5-0.8MPa

Gas consumption 400L/min

Power supply 380V/50Hz

Input power 15.5kW

Saw blade speed 3000r/min

Saw blade specification: Φ 500 × 4.3 × Φ 30mm

Cutting width Max 150mm (single piece)

Processing profile length range 6500 (set according to user needs)

Cutting height 150mm

Minimum cutting length 300mm

Dimensions 12500 × 4100 × 2100mm

Weight 3600kg

Hotline:

Hotline: