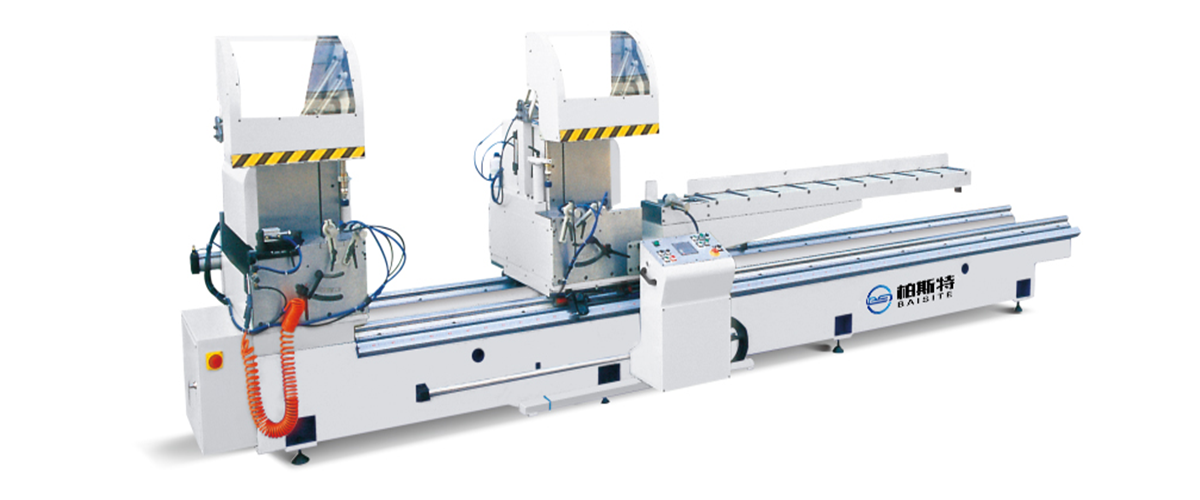

Aluminum profile CNC internal and external swing double head cutting saw LJZ2B-CNC-500 × 4200

Characteristic:

☆ Suitable for cutting aluminum profile end faces, completing automatic cutting of aluminum profiles with fixed length and angle; The two saw heads can independently swing at angles of -45 °, 90 °, and 45 °, which can be combined arbitrarily, using a cylinder transmission angle.

The bed body is welded with a steel structure and undergoes aging treatment to prevent deformation. The bed body is equipped with rust proof square guide rail motion pairs.

The two machine heads adopt a weighted casting integrated structure, which is processed as a whole to ensure the assembly accuracy and cutting accuracy of the equipment.

The two saw heads adopt square guide rails for working in, and the saw blade is directly connected to the motor, with high precision and smooth operation.

After the nose swing angle is in place, increase the cylinder hard limit to ensure accurate and error free angle rotation.

☆ Move the machine head to the side, using servo motor control combined with gear rack, ensuring smooth operation.

☆ When cutting with a saw blade, the protective cover of the machine head automatically falls down. After cutting is completed, the protective cover automatically opens to ensure cutting safety.

After the mobile machine head saw blade enters the cutting process, the tail material moves away from the saw blade and the saw blade retracts to prevent the saw blade from sweeping the material and ensure accurate cutting angles.

☆ Equipped with two sets of independent pneumatic landing assist material handling mechanisms in the middle. The movable saw head is equipped with a follow-up material rack to ensure that the longer profiles are fully in a stable state.

The profile clamping adopts a three position clamping structure, which can be independently controlled for use. Each machine head has horizontal and vertical compression.

The CNC system is equipped with cutting functions for ultra long and ultra short materials, as well as corner code cutting function.

Equipped with barcode printing function, select the printing content.

☆ Supports multiple languages and can be customized according to customer requirements.

The bill of materials can be automatically transmitted to the equipment through LAN or USB flash drive, which is convenient and accurate.

The standard diameter of the saw blade on this machine is 500mm and 550mm; larger saw blades can be customized for material cutting.

☆ Can choose to connect with software or ERP (optional).

Main technical parameters:

Power supply 380V 50Hz

Total power 7.0 KW

Motor power 2 × 3.0 kW

Speed 2800r/min

Working pressure 0.6-0.8MPa

Sawing angles of 45 ° and 90 °

Sawing range 200-6500mm

Saw blade specification: ? 550 × ? 30 × 4.4mm

Dimensions 5800 × 1600 × 1800mm

Weight 2000kg

Hotline:

Hotline: