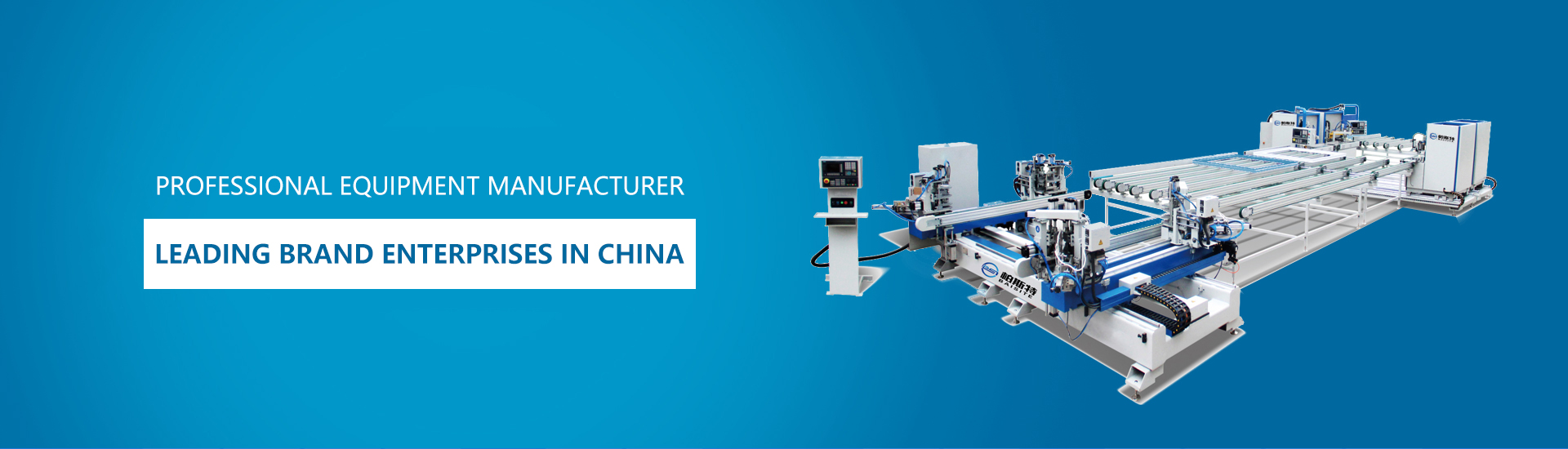

Aluminum profile CNC glass pressure bar saw LJY-CNC-350

Equipment function:

Used for 90 ° cutting of aluminum alloy door and window glass trim profiles.

Performance characteristics:

The machine adopts wireless measurement transmission technology, which can automatically complete the cutting of different specifications and sizes of door and window glass pressure strips, and can achieve barcode printing,

The equipment is equipped with German wireless measuring calipers, with a measurement accuracy of up to 0.01mm. The calipers are lightweight and easy to carry. The measured length data can be wirelessly transmitted to the machine's industrial control computer, which automatically receives real-time data with a transmission distance of up to 100 meters. The feed system adopts imported guide rail motion pairs, with high accuracy and good stability.

The machine tool is equipped with a CNC cutting frame to achieve CNC cutting.

The machine tool uses high-precision Italian motors to ensure smooth operation and high machining accuracy of the saw blade.

Hydraulic damping cylinder achieves uniform feed speed regulation and smooth saw blade cutting; Original imported hard alloy saw blade, with high processing accuracy and durability.

The workbench is equipped with an automatic waste collection guide groove for easy cleaning of equipment at any time.

The manufacturing mode that can realize the integrated manufacturing system (CIMS) of the entire factory, namely computer-aided design/process assistance/manufacturing assistance (CAD/CPP/CAM)

Main technical parameters:

Power supply: 380 V 50 Hz, three-phase five wire

Power: Approximately 4.5 kW

Working pressure: 0.5~0.8 MPa

Gas consumption: approximately 200 L/min

Saw blade specification: φ 350 × 3 × φ 30 × 120T

Saw blade speed: 2800 r/min

Operating speed: 0~10 m/min

Sawing length: 200-2500mm

Length error: ± 0.1 mm

Sawing angle: 90 °

Angle error: ± 2 ′

Dimensions (L × W × H): 7500 * 1800 * 1500

Weight: Approximately 800 kg

Hotline:

Hotline: