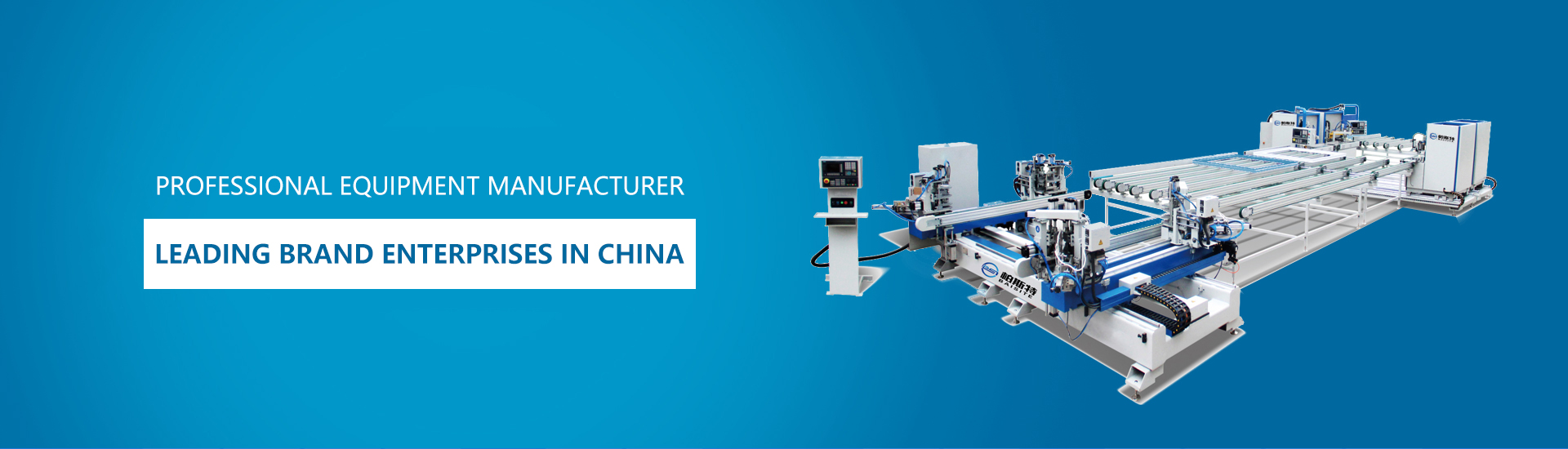

Stacking type fully automatic door and window gluing machine DJJ-CNC-02MD

Special equipment suitable for sealing the gap between door and window pressure lines and glass during the production process of doors and windows.

Using servo gluing and servo supply, the conversion speed between the two stations is 3 to 4 times that of a regular gluing machine, and the gluing speed is 1.5 times that of a regular gluing machine. The work efficiency is high, with a single shift of 700 to 800 window sashes (single-sided).

■ Uniform gluing, beautiful corners, no broken glue, high compactness.

■ Automatic size compensation system to compensate for the uneven diagonal of doors and windows affecting the adhesive effect.

Automatic size detection system, automatic corner system.

■ Stacking type gluing: After gluing one window sash, place a new sash on top of the already glued sash for gluing. Glue them in a stacked manner, and when about 15 sashes are stacked, use a forklift to fork them away; Reducing labor intensity, avoiding the trouble of platform type gluing machines and window sashes being lifted up and down, and improving work efficiency.

Main technical parameters:

Power supply 220V/50Hz

Minimum processing size: Window sash inner width: 210mm Window sash inner length: 300mm

Total power 4.0kW

Working pressure 0.6-0.8MPa

Dimensions 4450 × 2600 × 4500mm

Glue application speed 15~20min/min

Processing window sash length Max.3600mm

Processing window sash width Max 1200mm

Capacity per shift (8 hours) 700 to 800 window sashes (single-sided)

Hotline:

Hotline: